No products in the cart.

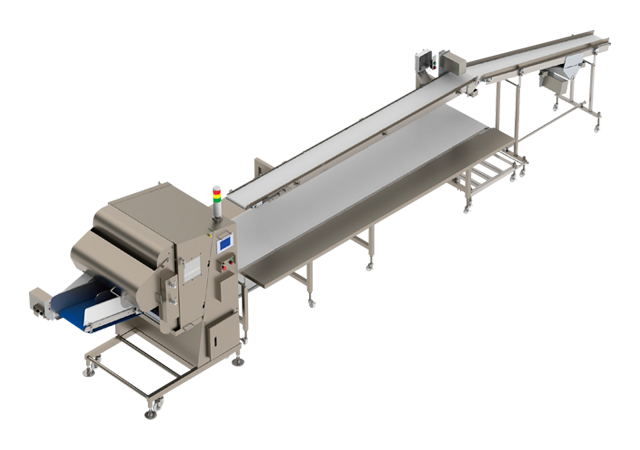

WPN-G321 High Speed Meat Slicer

Product Description

Galaxy 321

INNOVATIVE SLICER FOR YOUR EFFICIENT PRODUCTION LINE.

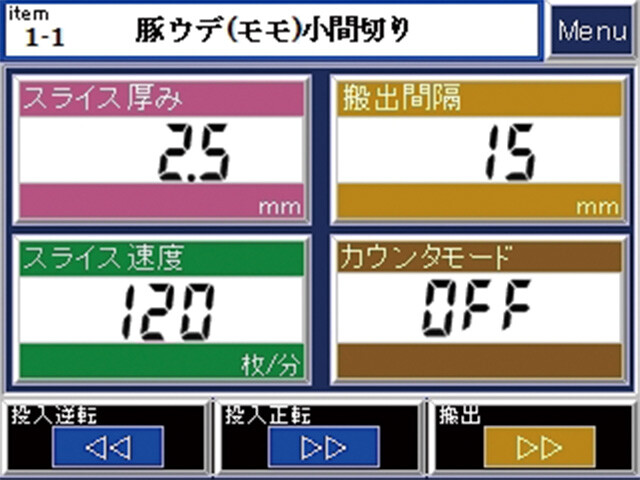

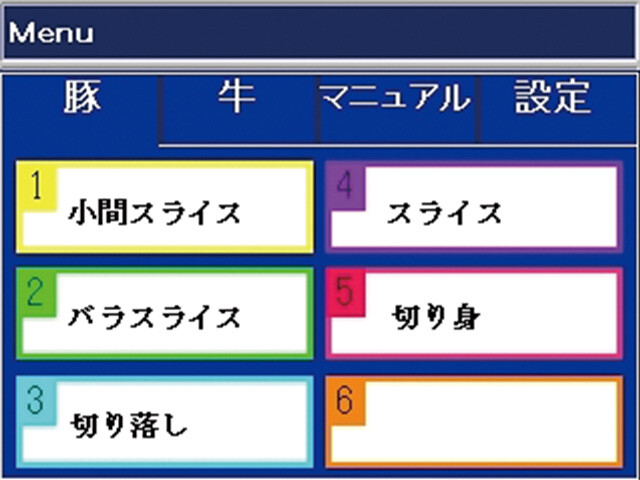

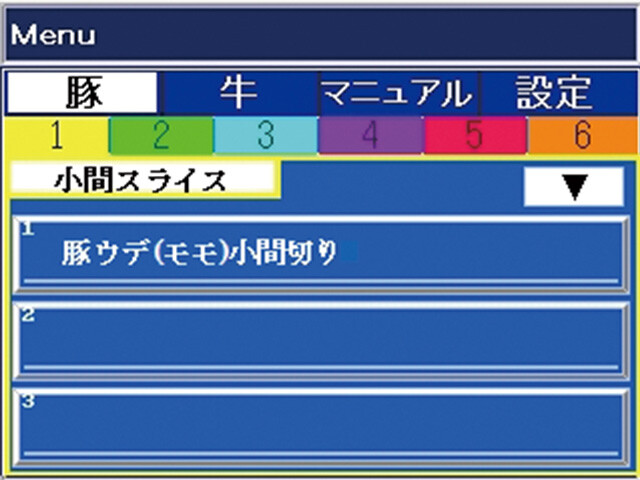

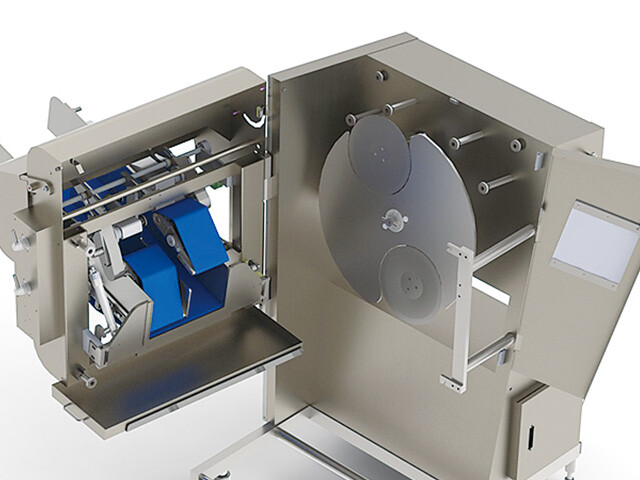

GALAXY/WPN-G321 was originally designed for a meatpacker/pc center who has the productivity issue on the slice meats for consumer tray. We call Koma(hushed slice) in japan. The quality slice and high yield are the characteristic points of the galaxy. Moreover, various types of outlet conveyors can be connected with the machine to go with the variety of customer inquiries.

Product Food Equipment Brand Watanabe

Overview

Details

| Product Details | • The full value of high production efficiency • Believing in our quality • Easy-to-use and simple touch panel • Hygiene • Safety • Saving the running cost |

|---|

| Construction | • Heavy Gauge stainless steel base, legs, head and door structure. |

|---|---|

| Standard Features | • Two saw blades, operation and parts manual, safety wall poster, end cut safety pusher plate. |

| Base Structure | • Stainless steel, removable door on both. |

$100.00

Brand: BiroRequest a Quote

| Your benefits at a glance | • Visually attractive fanning of the bacon (smoked, salted pork belly) • Continuously shingling and grouping (EB) • Product holder is available single- or double-row, is optimally suited for bacon / pork belly applications (thin and wide) • Back-feed path limitation (as a standard feature) for optimised processing even of short products • Easy cleaning of the machine • Available with conveyor belt |

|---|

$100.00

Brand: TreifRequest a Quote

| Construction | • Stainless steel base, Aluminum head standard; Stainless Steel head structure (optional – extra cost) |

|---|---|

| Standard Features | • Two saw blades • Operation and safety manual • Safety wall poster • End cut safety pusher plate. |

| Base Structure | • Aluminum, (optional stainless steel), entire assembly removable. |

$100.00

Brand: BiroRequest a Quote

| Capacity and cutting technology | • Basic model from the TWISTER family • Cutting capacity: up to 2,000 kg/h / 4,409 lbs • High output rate for cutting due to long cutting chamber (550 mm / 21 7/10") • Flexibility and strong performance thanks to choice between continuous and intermittent cutting • Best cutting quality through AVS and DHS |

|---|---|

| Economic efficiency | • Particularly cost-effective solution for perfect cutting quality in the mid-range performance class • Ergonomic, one-hand operating system for the closing of the product loading chamber • Optimum product compression due to automatic pre-pressing (AVS) |

| Cleaning and operator comfort | • Consistently ergonomic, even for cleaning • Easy access to all machine parts for cleaning • Gridset changes require no tools, thanks to the "Click&Go" grid set • A hygiene cylinder keeps the cutting chamber clean (optional) |

$100.00

Brand: TreifRequest a Quote