No products in the cart.

Twister Basic

The cost-efficient solution in the middle performance class

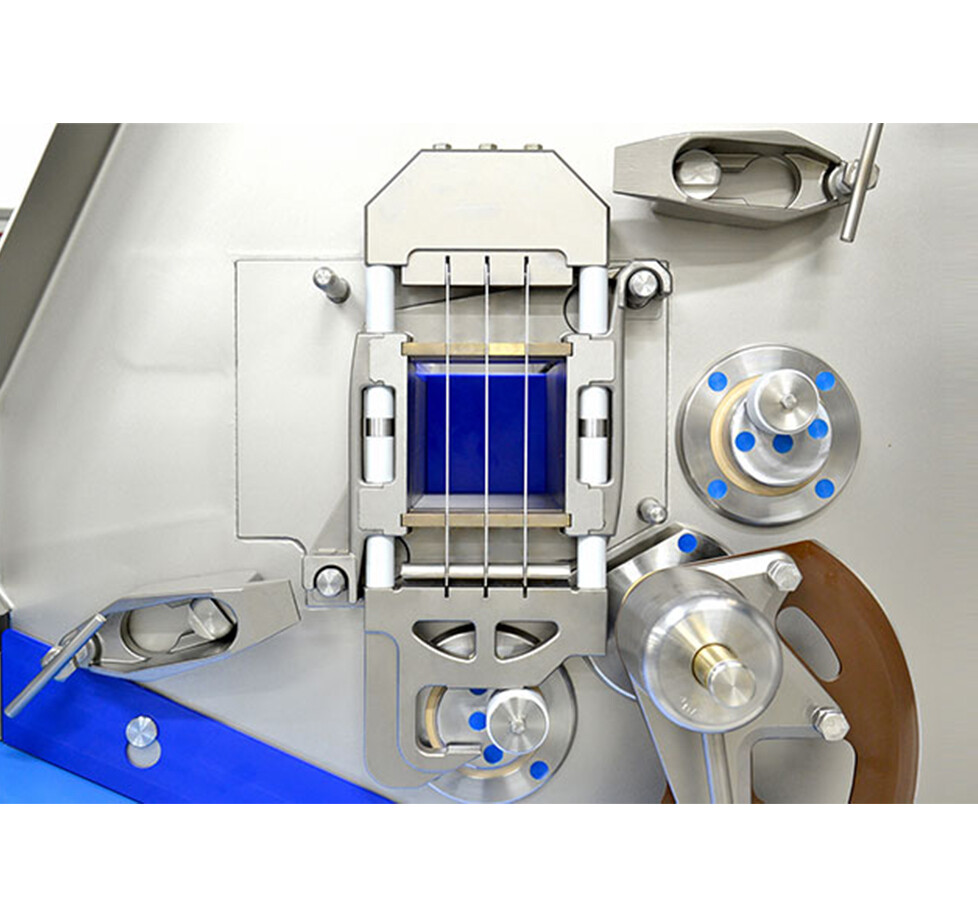

The dice and stripe cutter TWISTER basic is ideal for all who are looking for a cost-effective solution for perfect cutting quality in the mid-range performance class. In one hour the machine achieves an output of up to 2,000 kg, even during constant operation. The cutting chamber has a generous size of 550 x 120 x 120 mm (L x W x H), ensuring a high fill volume.

Product Food Equipment Brand Treif

Video Overview

Details

| Capacity and cutting technology | • Basic model from the TWISTER family • Cutting capacity: up to 2,000 kg/h / 4,409 lbs • High output rate for cutting due to long cutting chamber (550 mm / 21 7/10") • Flexibility and strong performance thanks to choice between continuous and intermittent cutting • Best cutting quality through AVS and DHS |

|---|---|

| Economic efficiency | • Particularly cost-effective solution for perfect cutting quality in the mid-range performance class • Ergonomic, one-hand operating system for the closing of the product loading chamber • Optimum product compression due to automatic pre-pressing (AVS) |

| Cleaning and operator comfort | • Consistently ergonomic, even for cleaning • Easy access to all machine parts for cleaning • Gridset changes require no tools, thanks to the "Click&Go" grid set • A hygiene cylinder keeps the cutting chamber clean (optional) |

| Capacity and cutting technology | • Slicing at Premium level — no conversions for different products necessary • Optimally suited for entry into the slicer business • Perfect product presentation thanks to SAS procedure combined with circular blade technology, even in the case of “difficult“ products, e.g. poultry – Ideal for processing veggie products • Patented vacuum gripper especially for soft products (optional) |

|---|---|

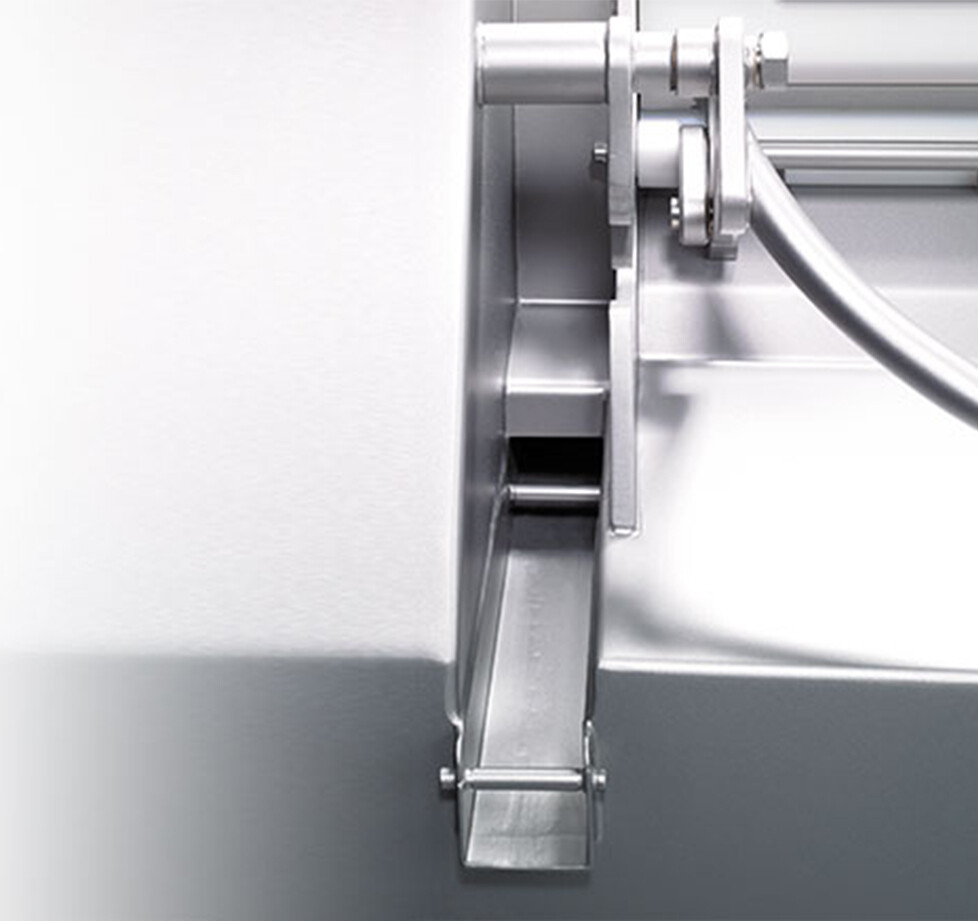

| Economic efficiency | • More time and fewer energy costs thanks to slicing at higher product temperatures • Space-saving design • Belt extension as a connection to the packaging machine with individually adjustable belt tilting (optional) |

| Cleaning and operator comfort | • Premium-Hygiene-Design • Open design and easy accessibility of the cutting area • No over-head blade change |

$100.00

Brand: TreifRequest a Quote

| Construction | • Heavy duty stainless steel hopper, lid, paddle, frame, and legs. Cast iron hot tin dipped bowl, ring, and auger (uses size 32 knife/plate. |

|---|---|

| Switch | • Watertight magnetic with thermal overload and under voltage protection |

| Standard Features | • Stainless steel 2nd grind paddle with center arms, 5” dia. Total lock swivel casters with anti-microbial wheels, spurt guard, extra rod for front, left or right side opening lid, power cord (see above), ring wrench, bowl nut wrench, two shear pins with screws, receptacle for electric footswitch ,operating and safety manual. |

$100.00

Brand: BiroRequest a Quote

| Construction | • Stainless steel base, Aluminum head standard; Stainless Steel head structure (optional – extra cost) |

|---|---|

| Standard Features | • Two saw blades • Operation and safety manual • Safety wall poster • End cut safety pusher plate. |

| Base Structure | • Stainless steel |

$100.00

Brand: BiroRequest a Quote

| Construction | • Body- Anodized Polished Aluminum Cast with Non-Corrosive Metal Frame |

|---|---|

| Standard Features | • Automatic spring loaded belt tensioning • Polygroove belt drive provides optimum performance • Blade protective ring guard prevents exposed blade edge during cleaning • Tilt-away product table lockout prevents thickness gauge from being opened during cleaning • Thermal overload/no volt release prevents accidental turn on after power outages • Green pushbutton on-off control and Red e-stop button • Water resistant IP 65 motor, wiring harness, electronic controls & connectors • Detachable sharpener assembly – helps provide hygienic slicing area • Product fence – for use on narrow products • 6-1/2′ Power Cord with 60 Hz – 115V • 3 prong molded plug – No plug on 50 Hz |

$100.00

Brand: BiroRequest a Quote

You may also like…

| Capacity and cutting technology | • Varied application options with regard to products and cutting processes (grating is also possible) • High output due to the extra-long cutting chamber (550 mm / 21 7/10”) • Multifunctional because continuous or intermittent cutting can be selected |

|---|---|

| Economic efficiency | • Optimum product compression due to automatic pre-pressing |

| Cleaning and operator comfort | • Consistently ergonomic even for cleaning |

$100.00

Brand: TreifRequest a Quote

| Your benefits at a glance | • High-performance and precision even with bone-in products • Fast and simple operation via touchscreen; USB connection for data backup and software updates • Optimum exploitation of the product as a result of residual piece optimization (E/EB) • Increased advantage as a result of the precision sickle blade and intelligent product feed holder • Optimum utilization of the product, for example by sectioning the product into slicing areas (E/EB) • Fast and easy cleaning thanks to optimum hygienic and ergonomic conditions (e.g., the discharge belt can easily be moved upright to the cleaning position without back strain) • Automatic ejection of the remaining piece due to pneumatic product holder (optional) • Travel gear to easily and flexibly move the machine (optional) • HS (High-Speed)-model for more capacity (optional) |

|---|

$100.00

Brand: TreifRequest a Quote

| Capacity and cutting technology | • Packing units / economy packs (optional) in accurate weight • High cutting performance: up to 2 t/h / 4,410 lbs per hour (depending on product and degree of filling) • Up to 50 cutting programs • High capacity also for smaller dices / strips enabled by the cutting force with up to 300 revolutions per minute of the blade |

|---|---|

| Economic efficiency | • Processing of various raw products • Highest possible product yield |

| Cleaning and operator comfort | • Consistently ergonomic, even for cleaning • Easy access to all machine parts for cleaning • Gridset changes require no tools, thanks to the "Click&Go" grid set • User rights on four levels |

$100.00

Brand: TreifRequest a Quote