No products in the cart.

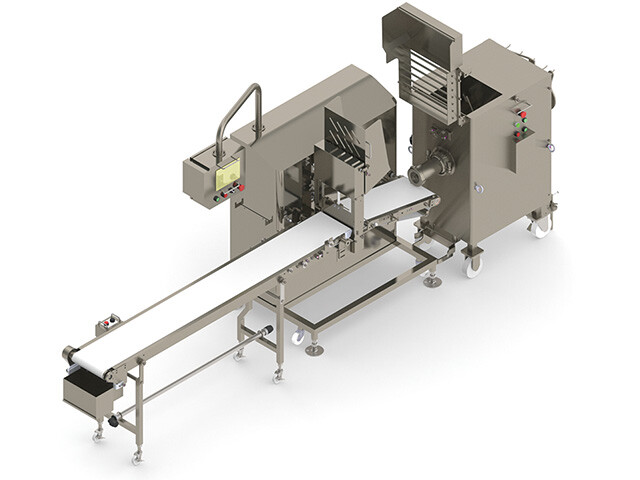

WBG-410 Frozen Meat Slicer

Product Description

Super Big 410

New Generation Frozen Slicer

High cleanability and technology frozen meat slicer can be washed down.

Product Food Equipment Brand Watanabe

| Construction | • Unitized stainless steel base, tables, leg bolt levelers, carriage channel & supports. Aluminum head and door, removable |

|---|---|

| Standard Features | • Two saw blades • Operation and Safety manual • Safety wall poster • End cut safety pusher plate |

| Blade Wheels | • 16” (40.64cm) single flange, cast iron, nickel plating, upper wheel assembly removable |

$100.00

Brand: BiroRequest a Quote

| Your benefits at a glance | • Visually attractive fanning of the bacon (smoked, salted pork belly) • Continuously shingling and grouping (EB) • Product holder is available single- or double-row, is optimally suited for bacon / pork belly applications (thin and wide) • Back-feed path limitation (as a standard feature) for optimised processing even of short products • Easy cleaning of the machine • Available with conveyor belt |

|---|

$100.00

Brand: TreifRequest a Quote

| Construction | • Heavy Gauge stainless steel base, legs, head and door structure. |

|---|---|

| Standard Features | • Two saw blades, operation and parts manual, safety wall poster, end cut safety pusher plate. |

| Base Structure | • Stainless steel, removable door on both. |

$100.00

Brand: BiroRequest a Quote

| Capacity and cutting technology | • Basic model from the TWISTER family • Cutting capacity: up to 2,000 kg/h / 4,409 lbs • High output rate for cutting due to long cutting chamber (550 mm / 21 7/10") • Flexibility and strong performance thanks to choice between continuous and intermittent cutting • Best cutting quality through AVS and DHS |

|---|---|

| Economic efficiency | • Particularly cost-effective solution for perfect cutting quality in the mid-range performance class • Ergonomic, one-hand operating system for the closing of the product loading chamber • Optimum product compression due to automatic pre-pressing (AVS) |

| Cleaning and operator comfort | • Consistently ergonomic, even for cleaning • Easy access to all machine parts for cleaning • Gridset changes require no tools, thanks to the "Click&Go" grid set • A hygiene cylinder keeps the cutting chamber clean (optional) |

$100.00

Brand: TreifRequest a Quote