- ×

BR-20 Compact Batter & Breading Machine 1 × $100.00

BR-20 Compact Batter & Breading Machine 1 × $100.00 - ×

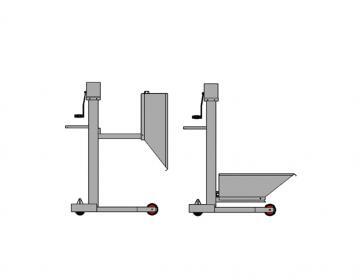

Stainless Steel Unloader Cart 1 × $100.00

Stainless Steel Unloader Cart 1 × $100.00 - ×

55 Meat Saw 1 × $100.00

55 Meat Saw 1 × $100.00 - ×

L-80 & L-80S Manual Linker 1 × $100.00

L-80 & L-80S Manual Linker 1 × $100.00 - ×

Cable Lift Dump Truck 1 × $100.00

Cable Lift Dump Truck 1 × $100.00 - ×

6 Tray Barbecue Machine 1 × $100.00

6 Tray Barbecue Machine 1 × $100.00 - ×

Twister Basic 1 × $100.00

Twister Basic 1 × $100.00 - ×

FC-20 Value Line Hydraulic Sausage Stuffer 1 × $100.00

FC-20 Value Line Hydraulic Sausage Stuffer 1 × $100.00 - ×

Puma 1 × $100.00

Puma 1 × $100.00 - ×

Stainless Steel Brine Pump Table 1 × $100.00

Stainless Steel Brine Pump Table 1 × $100.00

Subtotal: $1,000.00