- ×

3334SS STD. (16”) 1 × $100.00

3334SS STD. (16”) 1 × $100.00 - ×

B350A Gravity Feed Automatic Slicer 1 × $100.00

B350A Gravity Feed Automatic Slicer 1 × $100.00 - ×

DFS 50 Stuffer 1 × $100.00

DFS 50 Stuffer 1 × $100.00 - ×

TS-248 Steak Tenderizer 1 × $100.00

TS-248 Steak Tenderizer 1 × $100.00 - ×

Stainless Steel Double Tub Dolly 1 × $100.00

Stainless Steel Double Tub Dolly 1 × $100.00 - ×

30-60 Qt. Floor Mixer 1 × $100.00

30-60 Qt. Floor Mixer 1 × $100.00 - ×

Z1-H2700 Vertical Semi-Automatic Clipper 1 × $100.00

Z1-H2700 Vertical Semi-Automatic Clipper 1 × $100.00 - ×

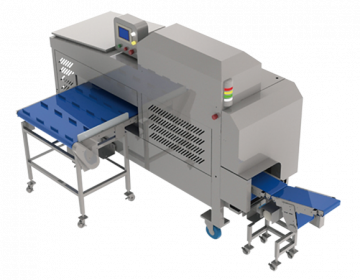

WPS-200R Portion Meat Slicer 1 × $0.00

WPS-200R Portion Meat Slicer 1 × $0.00 - ×

SSJ-AE 1 × $100.00

SSJ-AE 1 × $100.00 - ×

3334SS-4003FH (Fixed Head) 1 × $100.00

3334SS-4003FH (Fixed Head) 1 × $100.00 - ×

AFMG-24 Mixer Grinder 1 × $100.00

AFMG-24 Mixer Grinder 1 × $100.00 - ×

Axle Mounted Table Top Wrappers 1 × $100.00

Axle Mounted Table Top Wrappers 1 × $100.00 - ×

Stainless Steel Unloader Cart 1 × $100.00

Stainless Steel Unloader Cart 1 × $100.00 - ×

FC-30 INT Hydraulic Sausage Stuffer 1 × $100.00

FC-30 INT Hydraulic Sausage Stuffer 1 × $100.00 - ×

B350M Gravity Feed manual Slicer 2 × $100.00

B350M Gravity Feed manual Slicer 2 × $100.00 - ×

DMX and QUAD 500 HD 1 × $100.00

DMX and QUAD 500 HD 1 × $100.00 - ×

RM-20 Meat & Food Mixers 1 × $100.00

RM-20 Meat & Food Mixers 1 × $100.00 - ×

4 Half Pan Oven - 8 Half Pan Proofer 1 × $100.00

4 Half Pan Oven - 8 Half Pan Proofer 1 × $100.00 - ×

RS 112 Vacuum Stuffer Small Processor 1 × $100.00

RS 112 Vacuum Stuffer Small Processor 1 × $100.00 - ×

DMX and QUAD 200 1 × $100.00

DMX and QUAD 200 1 × $100.00 - ×

8160 Utensil Washer 1 × $100.00

8160 Utensil Washer 1 × $100.00 - ×

Puma 1 × $100.00

Puma 1 × $100.00

Subtotal: $2,200.00