No products in the cart.

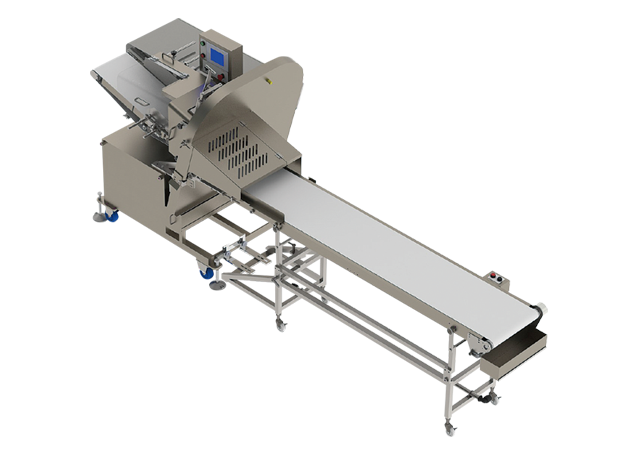

WTD-301 High Speed Meat Slicer

Product Description

Big Tornado

High Speed Slicer for Chilled Meat Patented.

Even pork belly fits in the Infeed conveyor.

A wide range of slices is promised.

Product Food Equipment Brand Watanabe

Overview

Details

| Product Details | • Amazing safety feature: Inter-Lock system. • Only takes a few minutes to disassemble for wash down. • Thickness Control by 0.1mm. |

|---|

| Construction | • Heavy duty stainless steel base, legs, fixed head, and door structures |

|---|---|

| Standard Features | • Two saw blades • Operation and safety manual • Safety wall poster • End cut safety pusher plate • Warranty registration card |

| Blade Wheels | • 16” (40.6 cm) cast iron, chrome nickel plating, upper wheel assembly lifts out |

$100.00

Brand: BiroRequest a Quote

| Construction | • Body – Anodized polished aluminum cast with non-corrosive metal frame |

|---|---|

| Standard Features | • Blade 13¾” (350mm) Hollow ground alloy steel (240 rpm) • Slice thickness adjustable 0-1” (0-25mm) • Maximum product cut, Round 9¼” (235mm) • Maximum product cut, Square 7 7/8 x 7 7/8” (200mm x 200mm) • Maximum product cut, Rectangle 11¾ x 6” (298mm x 152mm) • Automatic spring loaded drive belt tensioning • Blade protective ring guard prevents exposed blade edge during cleaning • Tilt-away product table lockout prevents thickness gauge from opening during cleaning • Thermal overload/no volt release prevents accidental turn on after power outages • Poly groove belt drive providing optimum performance • Water resistant IP65 motor, wiring harness and electronic controls • Product fence-for use on narrow products • Stainless steel product end weight • Detachable sharpener. |

$100.00

Brand: BiroRequest a Quote

| Your benefits at a glance | • High-performance and precision even with bone-in products • Fast and simple operation via touchscreen; USB connection for data backup and software updates • Optimum exploitation of the product as a result of residual piece optimization (E/EB) • Increased advantage as a result of the precision sickle blade and intelligent product feed holder • Optimum utilization of the product, for example by sectioning the product into slicing areas (E/EB) • Fast and easy cleaning thanks to optimum hygienic and ergonomic conditions (e.g., the discharge belt can easily be moved upright to the cleaning position without back strain) • Automatic ejection of the remaining piece due to pneumatic product holder (optional) • Travel gear to easily and flexibly move the machine (optional) • HS (High-Speed)-model for more capacity (optional) |

|---|

$100.00

Brand: TreifRequest a Quote

| Your benefits at a glance | • The 350 mm-wide insertion chamber allows plenty of space for numerous slicing applications, particularly for bulky products • High-performance and precision even with bone-in products • Increased speed in the production as a result of the backfeed limitation • Optimum utilization of the product, for example by sectioning the product into slicing areas and as a result of residual piece optimization (E/EB) • Fulfilment of the highest hygiene requirements as a result of labyrinth guidance • HS (High-Speed) more capacity (optional) |

|---|

$100.00

Brand: TreifRequest a Quote