No products in the cart.

F2000N/F3000N/F4000N Food/Patty Forming Machines

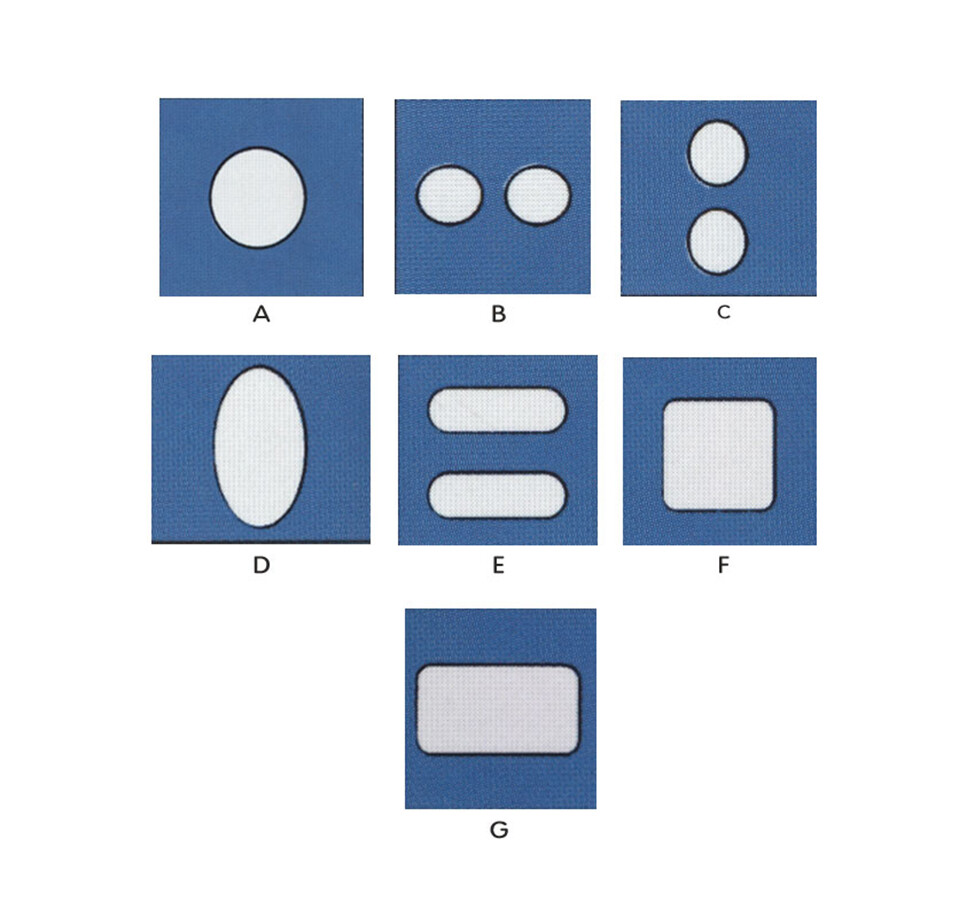

The BIRO F2000N, F3000N & F4000N Food / Patty Forming Machines are designed for the production of a wide variety of meat and food products, with maximum production output capability from approximately 2000 to 4000 formed products per hour. A large number of drum mold die shapes are available. They vary from the standard round shapes of different diameters to special shapes such as square, oval, rectangle, fish, cutlet, heart, chicken leg, chicken nuggets, rabbit, bone, tree, pork chop, etc. Call the factory for more information.

The key feature of this machine is the design of the Mold (die) in the drum. The operator can select product weights by changing the drum die depth (thickness) up to ¾” (19mm). You do not need different die cups and plates each time you want to change weights. The Food Former Models are compact, have a small footprint, and are easy to clean up. They are reliable, versatile, and are a real Value-Added Profit Center all their own.

Product Food Equipment Brand Biro

Specification

| F=Former; N=NSF; EH=Extended Hopper; 2000, 3000, 4000=cycles/hr | F2000N F2000EHN | F3000N F3000EHN | F4000N F4000EHN | |

|---|---|---|---|---|

| Product Type | Protein: Red Meat, Pork, Chicken, Fish, etc.. | |||

| Motor: 3/4HP (.56Kw), 115V, 60 Cy, 1 Ph.- 7.9A, IP55 | Standard | N/A | ||

| Motor: 3/4HP (.56Kw), 220V, 60 Cy, 1 Ph.- 4.0A, IP55 | Special Order @ EC | N/A | ||

| Motor: 3/4HP (.56Kw), 220V, 50 Cy, 1 Ph.- 4.4A, IP55 | Special Order @ EC | N/A | ||

| Motor: 1 HP (.75Kw), 115V, 60 Cy, 1 Ph.- 7.9A, IP55 | N/A | Standard | ||

| Drum Mold | White Poly – Select One Single Round Hole Mold Drum as Standard Equipment, from the Standard Selection Chart Below at No Up Charge. | |||

| 2 or more Drum Molds | Optional – Extra Cost – Advise Shape or Shapes required | |||

| Foot Switch – Start/stops former and conveyor | Standard Equipment | |||

| Product Hopper 6.5 Gal. – 25 L. (30 lbs.) | Std. Equipment on F2000N, F3000N, F4000N only | |||

| S.S. Feed Tray, detachable, 60 lb. (27.2kg) capacity | Optional – Extra Cost on F2000N, F3000N, F4000N only | |||

| Extended Product Hopper – 10.5 Gal. – 40 L. (60 lbs.) | Standard Equipment on all EHN’s only | |||

| Manual Wire Cleaner | Standard Equipment | |||

| Pneumatic Wire Cleaner – 65 PSI air minimum required | Optional – Extra Cost | |||

| Std. Conveyor Belt, 15-3/8” (390.5mm) long | Standard Equipment | |||

| Longer Conveyor Belt, 35-3/8” (898.5mm) long | Optional – Extra Cost | |||

| Extra Long Conveyor Belt, 45” (1180mm) long, included on frame with casters | N/A | |||

| Stainless steel feed paddles | Standard | |||

| Patty Paper Attachment – Accepts up to 5-½”(139.7mm) Square | Two – Sample Packs Included, 5” x 5” square, Approximately 1330 sheets | |||

| Variable Speed – Drum & Conveyor Synchronized | N/A | Standard Equipment | ||

| Cleaning Tilt Stand | Standard Equipment | |||

| N.S.F., E.T.L. Certification | Yes | |||

| Ledger: Protein = red meat, pork, chicken, fish, etc.; N/A = Not Available; S.S. = Stainless Steel; EC = Extra Cost; Std. = Standard. | ||||

Details

| product Type | Formers & Molders |

|---|

| Capacity and cutting technology | • Varied application options with regard to products and cutting processes (grating is also possible) • High output due to the extra-long cutting chamber (550 mm / 21 7/10”) • Multifunctional because continuous or intermittent cutting can be selected |

|---|---|

| Economic efficiency | • Optimum product compression due to automatic pre-pressing |

| Cleaning and operator comfort | • Consistently ergonomic even for cleaning |

$100.00

Brand: TreifRequest a Quote

| Your benefits at a glance | • High-performance and precision even with bone-in products • Fast and simple operation via touchscreen; USB connection for data backup and software updates • Optimum exploitation of the product as a result of residual piece optimization (E/EB) • Increased advantage as a result of the precision sickle blade and intelligent product feed holder • Optimum utilization of the product, for example by sectioning the product into slicing areas (E/EB) • Fast and easy cleaning thanks to optimum hygienic and ergonomic conditions (e.g., the discharge belt can easily be moved upright to the cleaning position without back strain) • Automatic ejection of the remaining piece due to pneumatic product holder (optional) • Travel gear to easily and flexibly move the machine (optional) • HS (High-Speed)-model for more capacity (optional) |

|---|

$100.00

Brand: TreifRequest a Quote

| Your benefits at a glance | • Visually attractive fanning of the bacon (smoked, salted pork belly) • Continuously shingling and grouping (EB) • Product holder is available single- or double-row, is optimally suited for bacon / pork belly applications (thin and wide) • Back-feed path limitation (as a standard feature) for optimised processing even of short products • Easy cleaning of the machine • Available with conveyor belt |

|---|

$100.00

Brand: TreifRequest a Quote

| Construction | • Heavy duty stainless steel base, legs, fixed head, and door structures |

|---|---|

| Standard Features | • Two saw blades • Operation and safety manual • Safety wall poster • End cut safety pusher plate • Warranty registration card |

| Blade Wheels | • 16” (40.6 cm) cast iron, chrome nickel plating, upper wheel assembly lifts out |

$100.00

Brand: BiroRequest a Quote

You may also like…

| Construction | • Body – Anodized polished aluminum cast with non-corrosive metal frame |

|---|---|

| Standard Features | • Blade 13¾” (350mm) Hollow ground alloy steel (240 rpm) • Slice thickness adjustable 0-1” (0-25mm) • Maximum product cut, Round 9¼” (235mm) • Maximum product cut, Square 7 7/8 x 7 7/8” (200mm x 200mm) • Maximum product cut, Rectangle 11¾ x 6” (298mm x 152mm) • Automatic spring loaded drive belt tensioning • Blade protective ring guard prevents exposed blade edge during cleaning • Tilt-away product table lockout prevents thickness gauge from opening during cleaning • Thermal overload/no volt release prevents accidental turn on after power outages • Poly groove belt drive providing optimum performance • Water resistant IP65 motor, wiring harness and electronic controls • Product fence-for use on narrow products • Stainless steel product end weight • Detachable sharpener. |

$100.00

Brand: BiroRequest a Quote

| Construction | • Body- Anodized Polished Aluminum Cast with Non-Corrosive Metal Frame |

|---|---|

| Standard Features | • Automatic spring loaded belt tensioning • Polygroove belt drive provides optimum performance • Blade protective ring guard prevents exposed blade edge during cleaning • Tilt-away product table lockout prevents thickness gauge from being opened during cleaning • Thermal overload/no volt release prevents accidental turn on after power outages • Green pushbutton on-off control and Red e-stop button • Water resistant IP 65 motor, wiring harness, electronic controls & connectors • Detachable sharpener assembly – helps provide hygienic slicing area • Product fence – for use on narrow products • 6-1/2′ Power Cord with 60 Hz – 115V • 3 prong molded plug – No plug on 50 Hz |

$100.00

Brand: BiroRequest a Quote

| Construction | • Stainless steel body, hopper, hopper cover |

|---|---|

| Standard Features | • Operating/Service manual • Drum & Hopper Cover, Safety Switches • Fixed Speed • Stainless Steel Feed Paddle • 15 ⅜”(390.5 mm) Conveyor Belt • Manual Wire Cleaner • 1- Single round hole drum, white poly (See Drum Mold below) • Auto-feed Paper Attachment (accepts up to 5½”(139.7 mm) square paper, two packs included with the machine. Approximately 1330 sheets.) • Disassembly for cleaning without tools. |

| product Type | Formers & Molders |

$100.00

Brand: BiroRequest a Quote

| Construction | • Stainless steel |

|---|---|

| Standard Features | • Two saw blades • Operation and parts manual • Safety wall poster • End cut safety pusher plate |

| Blade Wheels | • Hard tooth, three teeth per inch (8.5 mm between teeth), 142” (3606.8 mm) long x 5/8” (16 mm) wide, .022” (.56 mm) thick (two supplied with each saw) |

$100.00

Brand: BiroRequest a Quote